Health & SafetyMaximum safety through system design superiority

Operator safety is our first consideration when designing polyurethane processing equipment. Max Processor designs include features that minimize human exposure to potentially harmful vapors, liquids and solids. With safe practices, production workers can eliminate all bodily contact with process materials and work in an environment free of harmful vapors.

With ever increasing regulation and scrutiny on safe material handling, our goal is to provide the safest possible process solution through continuous design improvement and onsite training of your production staff.

Under normal conditions and with effective air management at the material discharge point, your employees should be able to work in an environment free of hazardous vapors. Similarly, with appropriate personal protective equipment and training, skin contact with hazardous materials can be eliminated.

New customers receive safety training as part of the new equipment installation process. Existing customers can request a one-time training session or contract for regularly scheduled training and maintenance sessions.

- Health and Safety Training

- Onsite safe practices course (combined classroom and hands-on)

- Quarterly training sessions

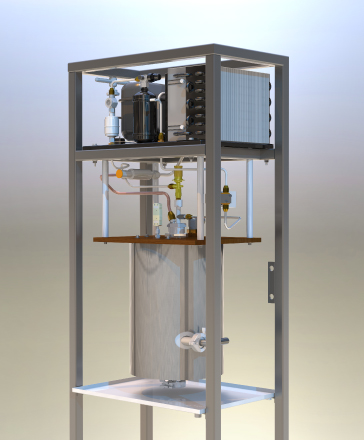

- Integrated vapor trap

- Refrigerated vacuum-based vapor condensation system

- Prevents hazardous vapors, extracted from materials in the degassing process, from entering the environment

- Fully contained liquid transfer system

- Vacuum transfer from supply drums or totes to process tanks

- No vapors entering process environment

- Fully contained pellet transfer and melting system

- No-human-contact MOCA handling system

- Hot fluid heating system eliminates over-temperature failures near hazardous and flammable materials

- Eliminates hot spots

- Eliminates ignition source related to heat system failure in close proximity to material storage or transfer

- No hazardous material leakage associated with external pumping systems

- Pumps are submerged in the process tanks

- Any pump leakage returns directly to the tank